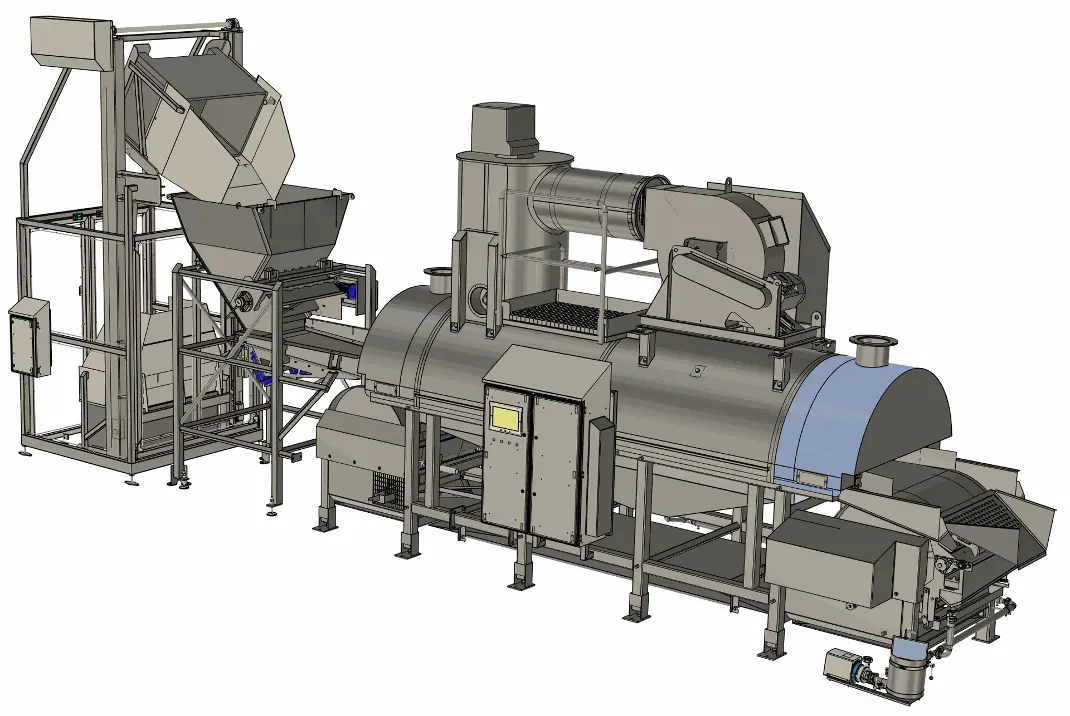

Coctio Roasting System

Designed for surface roasting of animal bones and handling liquid fat

Roasting of animal bones has never been this easy.

The Coctio Roasting System is designed to surface roast animal bones and other ingredients used in the production of bone broth and derivative products. In addition, it is designed to load ingredients automatically and recuperate fat that melts in the roasting process for ultimate ease of use.

The process is continuous and level of roasting can be adjusted by the speed at which ingredients pass through the oven and/or temperature inside oven.

To ensure consistency batch after batch, the processes are controlled by automation, removing potential human error from the roasting process.

The ready-built, tested line is installed in any facility within a matter of days, and only needs to be connected to utilities, such as steam, electricity, water and data.

Key Benefits

Consistent and continuous roasting

The Coctio

Oven enables continuous roasting of animal bones and other ingredients without

interruption.

Fat recovery and easy cleaning

Any fat that melts during the roasted process can be

recovered and redirected to a separate tank which can then be used for other

purposes.

Smell and smoke control

Exhaust connections at both ends of the oven force all smoke to be redirected outside and create a comfortable working environment while limiting the need for additional ventilation due to smoke or smell.

Easy set-up, Plug & Produce

Once delivered, the unit is typically ready to use after 1 week after utilities have been connected. The unit itself has a small footprint of only about 70 m2.

Equipment Overview

Process videos

Chicken bones roasting

Beef bones roasting

Culinary superfoods: Bone broth, Demi-glace, Sauces, Soup

Bone broth, clear stock, cloudy stock, ramen stock, pho, demi-glace, bone broth concentrates, ready sauces, ready soup, ready meals - the applications and end-products are endless