Animal bones: problem or opportunity?

Turning an overlooked by-product into profit and sustainability

Global consumption of fresh meat continues to increase year after year. As a result, slaughterhouses and meat and fish processing plants generate enormous volumes of beef, pork, poultry and fish bones as a side stream to their core business. This growing amount of bone residue, among other waste materials, represents a significant operational burden, but also an incredible opportunity.

The handling of bones represents a substantial cost for the industry. Traditionally, these bones have been treated as waste and sent for rendering, generating ongoing disposal fees, logistics costs and administrative burden. In addition to high disposal costs, this leads to the loss of valuable nutrients and unnecessary emissions. For example, in Finland, meat producers have paid at least 0,18€ per kilogram for the disposal of bone residues and such costs are expected to increase further in the future. At scale, this creates substantial annual expenses for slaughterhouses and food producers — costs that do not contribute to revenue or product differentiation.

At the same time, this stream of bones represents a largely untapped opportunity. Globally, around 91 billion kilograms of animal bones are produced every year, accounting for roughly 18% of an animal’s live weight. Treating such a large and consistent material flow purely as waste leads to the loss of valuable nutrients, energy and commercial value. Animal bones are often categorized as Category 3 bones and regarded as animal by-products under EU Regulation (EC) No 1069/2009. However, in most cases, they originate from animals that were approved for human consumption and can therefore be utilized further, provided they remain within the appropriate production chain. In practical terms, these bones represent low-risk materials with significant value creation potential.

Rather than being seen only as a disposal challenge, bones can be recognized as a high-potential raw material. When handled strategically, they offer food producers the possibility to reduce costs, improve sustainability performance and create entirely new value streams. In this sense, bones are not only a problem to be managed — they are a resource waiting to be fully utilized.

Bones as a valuable raw material

Animal bones are a nutrient-rich and versatile raw material, containing:

- Flavour compounds, collagen, proteins and amino acids used in food, nutraceutical and cosmetic industries

- Calcium, phosphorus and minerals essential for nutrition and agricultural soil improvement and fertilizers

- Natural fats that can be rendered into biodiesel or used as renewable process energy

When properly utilized, these components enable high-value outputs such as:

Food for human consumption

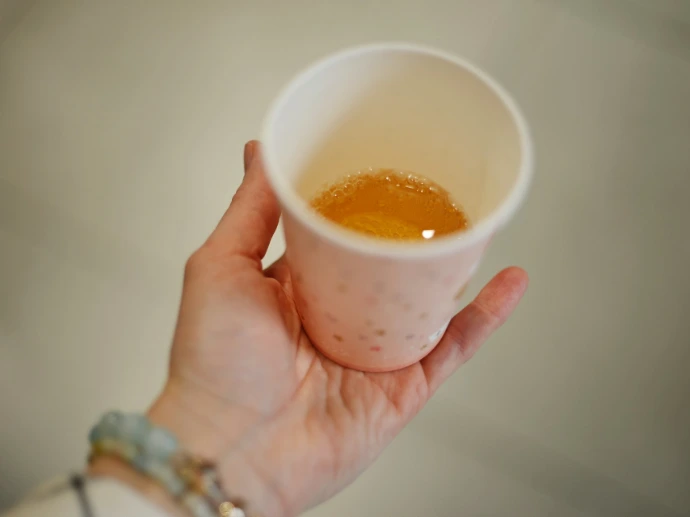

Industrial-scale production of bone broth, stocks, demi-glace,

sauces and ready meals.

Clean-label products

Matching consumer demand for naturality, health benefits and short ingredient lists.

Functional and wellness-oriented foods

Ready-to-consume broths, functional beverages and natural flavour bases.

Oleochemicals

Used in cleaning products, cosmetics, lubricants and other industrial applications.

This approach transforms animal bones from a disposal problem into a profitable side stream, fully aligned with the principles of the EU Circular Economy, which aims to keep resources in productive use for as long as possible while minimizing waste generation.

Coctio’s Role in the Circular Bone

Economy

At Coctio, we help food producers turn animal bones into high added-value products through advanced, automated process solutions for bone broth, stock and derivatives production. Instead of disposing of underutilized Category 3 bone material at a low or negative value, the Coctio process solution enables meat, fish, and food processors to achieve a significantly higher yield from bones. Economic studies show that added-value processing of bones can deliver net gains starting from 0,50€ per kilogram, while simultaneously reducing waste and supporting environmental targets.

Coctio systems allow companies to:

- Reuse bones generated in their own production lines

- Create net profit starting from 0,50€/kg of bones

- Extract valuable flavour and nutrition (collagen, proteins and minerals) to create clean-label, natural and profitable food products

- Reduce waste disposal fees and overall environmental impact

The result is a closed-loop process in which every part of the animal is utilized efficiently — aligning business performance with sustainability goals.

Coctio solutions support sustainable profitability in manufacturing operations by reducing slaughterhouse and landfill waste, as well as emissions, compared with conventional animal by-product processing and rendering practices.

Furthermore, consumer demand is increasingly shaping the food market. Products that combine natural ingredients, nutritional value, clean-label formulations and responsibly sourced raw materials are driving growth across multiple categories. Sustainability is no longer a secondary consideration, but a central factor in purchasing decisions.

Food producers that integrate these principles into their manufacturing processes are better positioned to differentiate their portfolios, improve operational efficiency and respond to evolving market expectations. As a result, companies that align product development with wellness and sustainability trends are consistently more competitive and better placed for long-term financial success.

Value-added method feeds people, not landfills

Reusing bones within the food industry supports the EU Circular Economy objectives:

- Resource efficiency: keeping valuable raw materials in productive use

- Waste reduction: minimizing landfill use and emissions from rendering

- Sustainability: reducing carbon footprint and supporting renewable energy production

By viewing bones not as waste but as

opportunity, the industry can move toward a more profitable and sustainable

future — feeding people, not landfills.

Bone broth

Culinary superfood?

Even if it may seem that bone broth is a novel product, its roots go much farther - also known as liquid stock - it has been the staple ingredient of restaurant chef's for centuries and for good reason.