Coctio Cooker System

The ultimate cooking system for bone broth, stock, ramen, pho...you name it

The easiest and fastest way to get started with industrial production of 100% natural bone broths and stocks

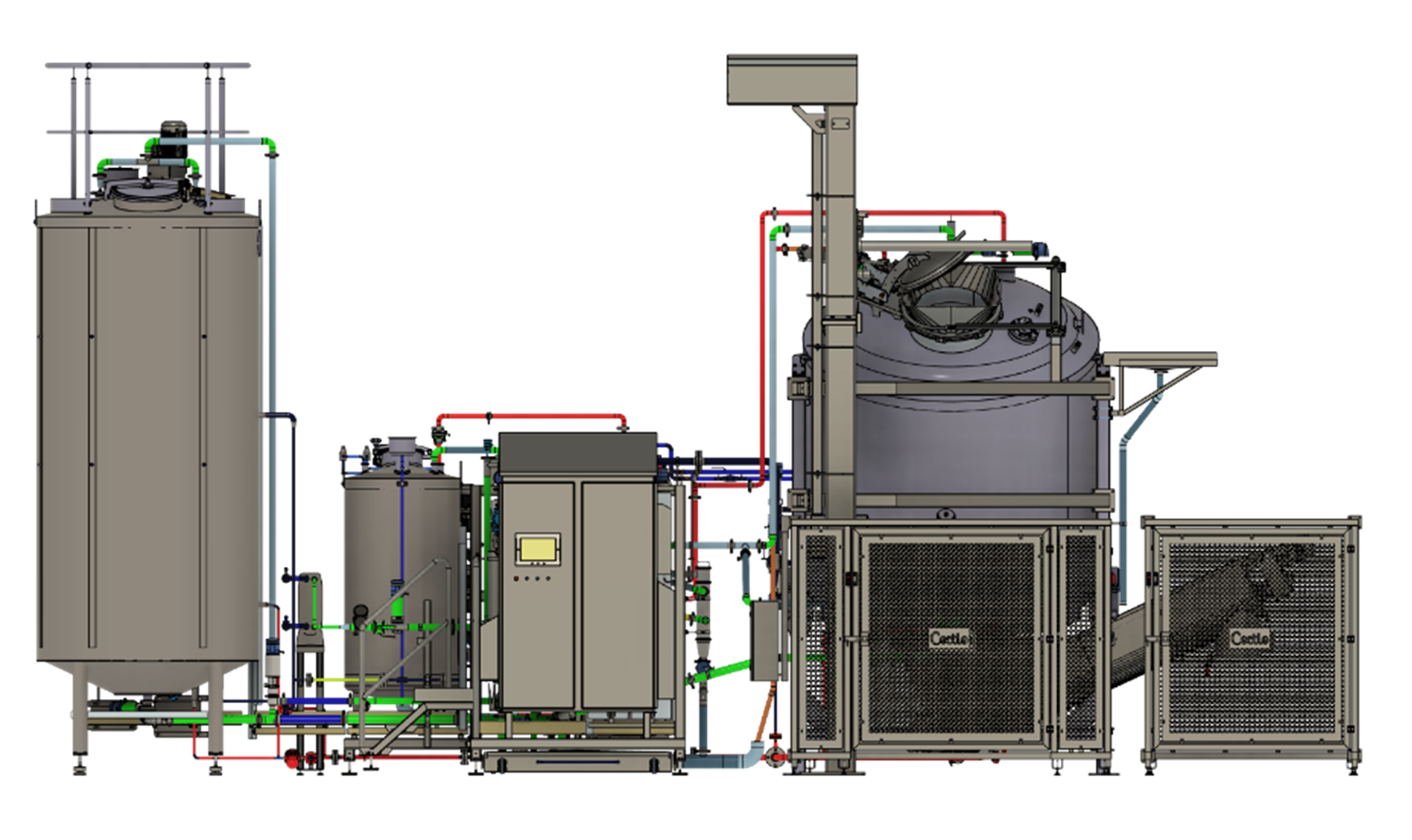

The compact, Coctio Cooker System is an ideal solution to quickly start the production of protein-rich, full of flavour natural bone broths and stocks at an industrial scale. The equipment is designed specifically to replicate the same processes undertaken by a professional chef in its own kitchen, aiming to create powerful natural flavours with raw ingredients that are in most cases regarded as waste streams.

To ensure consistency batch after batch, the processes are controlled by automation, removing potential human error from the cooking process which is typically a major issue for most restaurant chefs and other producers alike. In addition, the system can cook unsupervised overnight with no operators on-site dramatically lowering operating costs.

If you wish to have an all encompassing system, the Coctio All-in-One-System includes also a heated storage tank and automated CIP washing system.The objective of the AiOS system is to provide the easiest first step to start producing bone broths and stocks on an industrial scale, otherwise almost impossible to achieve on smaller professional kitchen equipment which require a lot of supervision and make it difficult to produce consistent end-product quality.

The ready-built, tested line is installed in any facility within a matter of days, and only needs to be connected to utilities, such as steam, electricity, water and data.

The Coctio AiOS is without a doubt, the easiest way to get started with industrial production of bone broth and to extract all of the nutritional and taste value remaining in the category 3 bones , otherwise discarded to landfills.

Coctio AiOS System

The easiest and fastest way to get started with industrial production of natural bone broths and stocks

- Complete Coctio Cooker System

- Heated storage tank with mixing

- Simple CIP automated washing

Coctio Cooker System

The ultimate automated natural bone broth cooking system

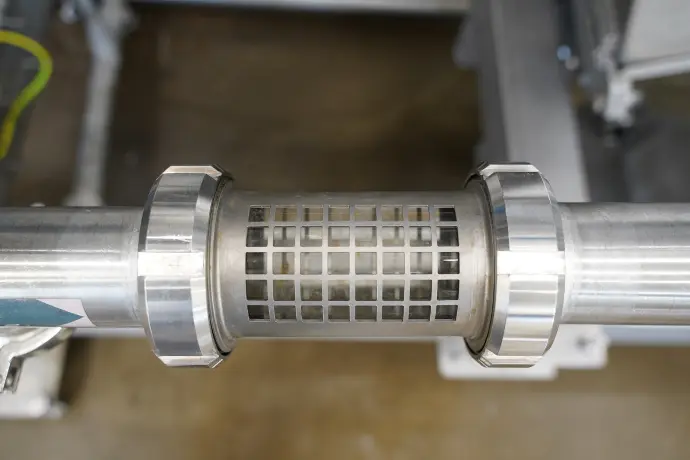

- Closed Cooking vessel with up to 3 bar gauge or 140 degrees C

- Unique Coctio Proprietary Automated Boiling Contol System

- Soft cooking with indirect steam jackets

- Vertical pillar lift-and-tip ingredient loading

- Cooked ingredient extraction screw conveyor

- Broth and Liquid fat extraction pump

- Automated fat separation

- and more

Key Benefits

100% Natural bone broth production

Produce from basic to michelin-star bone broths using the proven Coctio technology that emulates the same processes that restaurant chefs use in their professional kitchens, requiring no additives in the process.

Cost-Effective Processing

Coctio AiOS unit delivers unbeatable benefits in terms of productivity and reduces OPEX in comparison to more traditional equipment, as its processes are mostly under automated control requiring very little supervision.

Consistency and safety with automation

The system is closed and controlled by automation which ensures consistency batch after batch and minimizes potential human error in the production process. The actual cooking process takes some time but does not require active supervision - the automated control will safely take care of the cooking.

Easy set-up, Plug & Produce

Once delivered, the unit is typically ready to use after 1 week after utilities have been connected. The unit itself has a small footprint of only about 40 m2.

Equipment Overview

Process videos

Step 1

Load ingredients

Step 2

Cooking

Step 3

Extract liquid broth

Step 4

Extract liquid fat

Step 5

Extract cooked ingredients

Culinary superfoods: Bone broth, Demi-glace, Sauces, Soup

Bone broth, clear stock, cloudy stock, ramen stock, pho, demi-glace, bone broth concentrates, ready sauces, ready soup, ready meals - the applications and end-products are endless